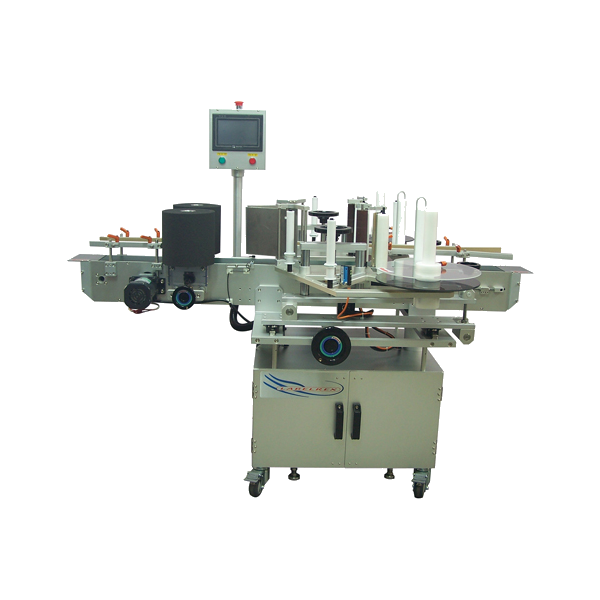

PML-610/620E automatic economy-type flat bottle (single/two-sided) labeling machine

Applicable scope:

Foods, chemicals, pharmaceutical products, cosmetics, electronics, hardwares, auto parts, stationery items, batteries, cartons, different kinds of oil, and packaging of various specifications.

Features:

1.Quality and aesthetic machine design in stainless steel and anodized aluminum alloy

materials.

2.EasyView color HMI touch-screen operation.

3.Label driving in (Japanese-made) Yaskawa servo motor.

4.Conveyor driving in (Japanese-made) Mitsubishi inverter and Oriental AC motor.

5.Mitsubishi PLC and Keyence photo sensors from Japan are used.

6.Optional automatic bottle distribution device.

7.Adjustable conveyor belt height to cope with prodution need.

8.Labeling accuracy is ±1mm.

9.Labeling speed: 18m/min (60 ~ 120pcs/min depending on objects to be labeled).

10.Sharp printing result using hot stamp printing system (optional).

11.Labeling position, height and angle can be adjusted with a hand wheel.

12.Automatic machine shutdown when there is no label stock (optional).

13.Bottle centerizing and positioning, label roller leveling, label disc advancing and

retracting adjustment, etc.

| Machine dimensions | 1600 x 1500 x 1500mm (L x W x H) |

| Conveyor belt size | 1600 x 125 x 750mm (L x W x H) |

| Machine weight | 150 kg |

| Maximum labeling size | 300 x 120mm (L x W) (can be widen up to 180mm) |

| Label roll size | Max. outer ø 310mm, paper core inner ø 76mm |

| Power rating | Single-phase220V 50 / 60 HZ |